In an increasingly competitive agricultural industry, efficiency and innovation are paramount. Modern poultry farming techniques have dramatically evolved, embracing sophisticated technologies to enhance productivity and sustainability. A perfect example of this progression is seen in the adoption of the 5 Tiers H Type battery cages system, designed meticulously for housing 60,000 laying hens. This solution, tailored to a large-scale poultry farm, combines advanced housing architecture and automation to optimize operations and animal welfare.

Design and Specifications of the H-Type Battery Cages

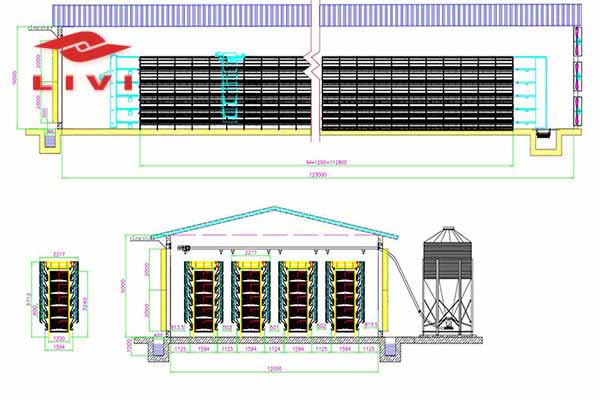

The facility occupies a substantial area measuring 120 meters in length, 13 meters in width, and 5 meters in height. It strategically designed to maximize space and facilitate farm management activities. Within this expansive shed, the H-Type battery cages are systematically arranged in four rows, each comprising 84 sets of cages. Each set is specifically engineered to accommodate 180 laying hens, ensuring adequate space and comfort.

The H-Type 5-tier cage itself is a marvel of agricultural engineering. Measuring 1200mm by 625mm by 480mm per unit, this configuration not only makes efficient use of vertical space but also enhances accessibility for egg collection and routine maintenance. Constructed with robust materials, the cages ensure durability and are easy to clean, which is crucial for maintaining hygiene and preventing disease spread.

Integration of Automation

To elevate the farm to state-of-the-art levels, the poultry house is equipped with comprehensive automated systems. This includes automatic feeding, egg collection, manure removal, and environmental control systems—each playing a vital role in streamlining the farm operations and minimizing labor costs.

Automated Feeding System: Ensures that each hen receives the precise quantity of feed required, adjusted according to age and production phase, directly delivered to the cages at predetermined intervals.

Automated Egg Collection System: Designed for gentle handling, the system efficiently transports eggs from the cages to a central collection area. It reduce manual labor and minimizing the risk of egg damage.

Automated Manure Removal System: Essential for maintaining cleanliness and health standards, this system periodically clears manure from underneath the cages, thereby controlling ammonia levels and reducing the potential for disease.

Environmental Control System: Perhaps one of the most critical systems, this regulates ventilation, temperature, and humidity within the barn. Sensors continuously monitor environmental parameters to ensure optimal conditions for the hens, thus promoting higher productivity and well-being.

Solution Of 60000 Chickens In H Type Battery Cages

Benefits and Implications

The adoption of the H-Type 5-tier battery cage system and its accompanying technologies not only maximizes the use of space but also enhances the overall welfare of the poultry. It ensures that hens live in a controlled environment, receive balanced nutrition, and are protected from elements and potential predators. Moreover, this system significantly reduces the environmental footprint of the farm by optimizing resource use and reducing waste.

Furthermore, the automation aspects highly relieve the burden on farm workers. It allow them to focus on monitoring the flock’s health and productivity rather than routine tasks. This can lead to more strategic management and operation of the farm, placing an emphasis on sustainability and efficiency.

Conclusion

The modern poultry farmer must navigate a complex array of challenges, from economic pressures to environmental concerns. The implementation of the H-Type 5-tier battery cage system in a poultry enterprise illustrates a forward-thinking approach to addressing these challenges. It is not merely a housing solution but a comprehensive management framework that promises a revolution in poultry farming. With such innovations, the future of agriculture looks not only more productive but also more sustainable and humane.