Efficiency and automation are key in modern poultry farming practices. This article explores a comprehensive solution for managing a 40000 layers within automatic chicken cages.

Setting Up the Infrastructure

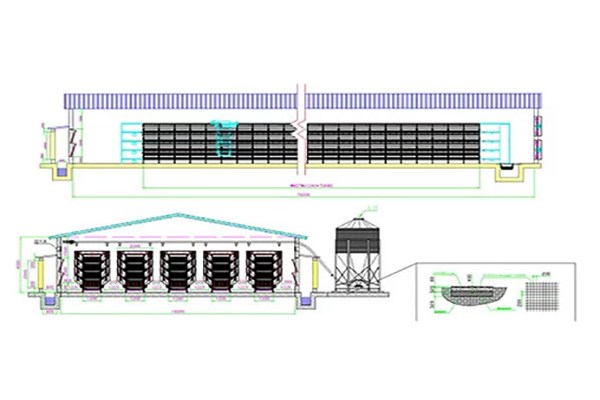

Chicken House Dimensions: The poultry farm encompasses a shed measuring 75 meters in length, 15 meters in width, and 4 meters in height.

Chicken Cage Configuration: H-type layer automatic chicken cages are chosen, featuring four tiers and two doors, with each set capable of housing 144 layers.

Poultry Cage Requirement: To accommodate 40,000 layers, a total of 280 sets of H-type egg chicken cages are necessary.

Essential Chicken Raising Equipment

Automated Feeding Systems:

- Function: Ensures timely and precise distribution of feed to the layers, optimizing their nutrition intake.

- Quantity: Five sets of automated feeding equipment.

Automated Manure Removal Systems:

- Function: Maintains cleanliness within the poultry shed, promoting the health and well-being of the layers.

- Quantity: Five sets of automated cleaning equipment.

Environmental Control Systems:

- Function: Regulates temperature, humidity, and ventilation within the poultry shed, creating an optimal environment for the layers.

- Importance: Critical for promoting growth and productivity.

Feed Silos:

- Function: Stores feed to ensure uninterrupted supply to the layers.

- Importance: Provides a constant and accessible source of feed.

Conclusion

By integrating automated feeding and cleaning systems, environmental control equipment, and feed silos into the poultry farm setup, farmers can optimize operations, increase productivity, and ensure the welfare of their layers. This comprehensive solution represents a modern and effective approach to poultry farming, enabling farmers to meet the growing demand for chicken raising equipment while ensuring sustainability and profitability.

If you would like a free chicken design or buy chicken raising equipment, please leave us a message.