In the solution of a chicken farm design to house 200,000 layers, several key components are essential to ensure efficient operation and animal welfare. Here’s a breakdown of the solution:

Farm Infrastructure:

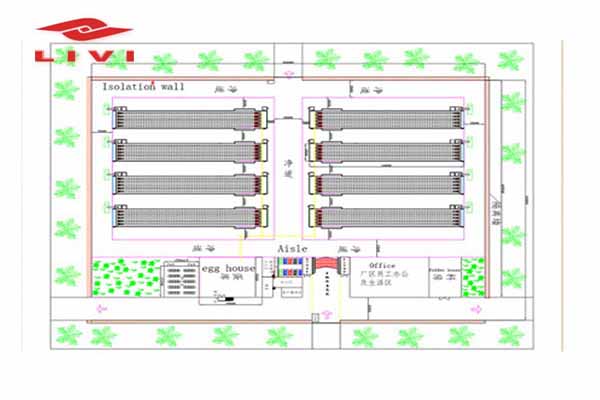

- Eight equally sized chicken houses are constructed within the farm compound.

- Additional facilities include an egg storage area, staff office and living quarters, feed storage, manure management zone, disinfection area, and green spaces for environmental aesthetics.

Chicken House Dimensions:

- Each chicken house measures 55 meters in length, 15 meters in width, and 4.5 meters in height.

- The overall dimensions of the farm are 150 meters by 100 meters.

Housing Distribution:

- The 200,000 layers are distributed across the eight chicken houses, with each house accommodating 25,000 hens.

Equipment and Automation:

- H-type layer cage farming equipment is employed in the chicken houses.

- The system includes automated features such as manure removal, feeding, egg collection, and environmental control.

- Within each chicken house, 160 sets of H-type layer cages are installed, arranged in four rows with 40 sets per row.

Operational Efficiency:

- Automation streamlines tasks, reducing labor requirements and ensuring consistent care for the layers.

- Proper ventilation and temperature control provided by the environmental control system optimize conditions for bird health and egg production.

- Regular disinfection protocols in designated areas minimize the risk of disease outbreaks.

Sustainability Considerations:

- Efforts are made to incorporate green spaces within the farm compound, enhancing environmental sustainability and providing a pleasant working environment for staff.

By implementing these chicken farm design and operational strategies, the chicken farm can effectively house and manage a large population of layers, promoting productivity, welfare, and sustainability.

If you want to build a modern chicken house, please leave us a message to get a free quote on automated chicken equipment.