A Type Layer Battery cage(5000-30000 chickens)

Material: International Q235 steel

Anti-corrosion Treatment Process: Hot-dip Galvanized, Aluminum-Zinc Alloy

Chicken breed: Layer

Number of chickens raised: 5000-30000 layers

Lifespan: 15-20 years

Product Introduction

Layer farming is an area that requires scientific management and efficient equipment. As A representative of modern breeding, the A-type egg cage has injected new vitality into the breeding industry. Type A layer cage is A unique structure, layer on layer design, shaped like the letter “A”, to provide a stable living environment for laying hens. This design not only maximizes the coop space, but also provides a stable living space for the flock.

The specific introduction of A type layer cage is as follows:

| Brief Details | |

| Material | International Q235 steel. |

| Anti-corrosion Treatment Process | Hot-dip Galvanized, Aluminum-Zinc Alloy |

| Lifespan | 15 – 20 Years |

| Certificate | ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC |

| Production Lead Time | Depending on the order quantity. Normally about 10 days for 20ft container, 15 days for a 40ft container. |

| Supply Ability | 10000 Set/Month |

| Packing Method | Normal export packing. 20ft / 40ft container. |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF |

Specification of A type layer battery cage

The commonly used specifications of A type layer battery cage mainly have three layers and four layers.

| A-type Layer Chicken Battery Cage Specification | ||||

| Type | Model | Birds Qty/Door | Birds Qty/Unit | Specification |

| A-Type | 3-Tier 4-Door | 4 pcs | 96 pcs | 1950mm*350mm*380mm |

| 3-Tier 5-Door | 3 pcs | 90 pcs | 1950mm*350mm*380mm | |

| 4-Tier 4-Door | 4 pcs | 128 pcs | 1950mm*350mm*380mm | |

| 4-Tier 5-Door | 3 pcs | 120 pcs | 1950mm*350mm*380mm | |

| 4-Tier 5-Door | 4 pcs | 160 pcs | 1950mm*450mm*410mm | |

Characteristics of A type layer battery cage

Maximizing space: The A-shaped design allows the farm to make more efficient use of limited space and maximize the number of chickens per square meter.

Convenient management: The layered structure of the cage provides farmers with more convenient management methods, including feeding, cleaning, disease monitoring, etc., making daily operation smoother.

Good ventilation: The design of the cage helps to circulate air, maintain good ventilation, provide a suitable living environment, and help the growth and production of laying hens.

Basic chicken equipment

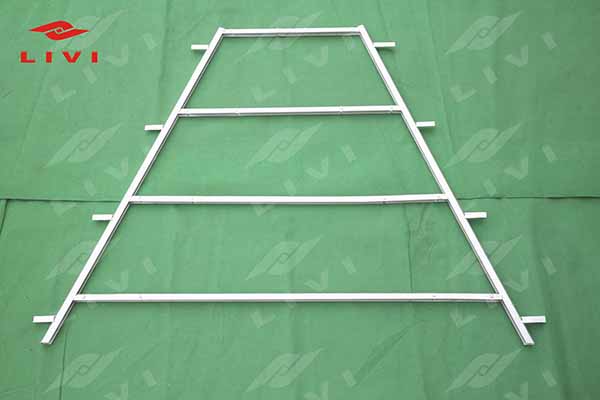

chicken cage frame

Solid construction: A strong material, such as steel. Ensure that the system is structurally.

Hierarchical design: Multi-layer design, forming an A-shaped structure, so that the chickens can live in order at different levels.

chicken cage net

Material: High quality metal material to ensure durability and corrosion resistance.

Grid design: Ensure ventilation and observation.

chicken throuhg

Location design: The food tank ensure that each chicken can easily get enough feed.

Material health: The trough is made of easy to clean and corrosion-resistant materials to ensure the health and safety of feed

chicken drinking line

Automatic water supply: It ensures that the chickens have access to clean and fresh water at all times.

Leak-proof design: Plumbing systems are often leak-proof in design, reducing water waste.

Automated chicken raising equipment

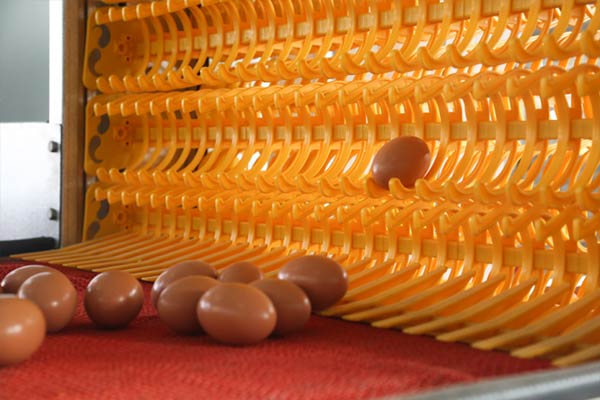

Egg collecting equipment

The introduction of egg collection equipment enables an efficient egg collection process, with key features including:

Automatic collection: The egg collection equipment can automatically collect eggs in the chicken house, reducing the labor intensity of manual egg collection.

Breakage-proof design: The equipment design takes into account the breakage-proof of the egg to ensure the quality and integrity of the egg.

Chicken manure cleaning equipment

Automated manure removal equipment is an important tool for maintaining chicken coop hygiene. Key features include:

Automatic cleaning: Cleaning equipment can automatically clean, effectively reduce the impact of feces on the health of chickens.

Efficient cleaning: The equipment design can efficiently clean up the feces in the chicken house, reduce labor costs, and improve the cleaning effect.

Chicken Feeding Equipment

The introduction of automated feeding equipment makes the feed delivery more precise and orderly. Key features include:

Automatic feeding: The feeding equipment can automatically feed according to the preset time and amount to ensure that the chickens get adequate nutrition.

Uniform distribution: The feeders are designed to achieve an even distribution of feed, avoiding waste and ensuring that each chicken gets enough feed.

Environmental control equipment

Automated environmental control equipment helps to provide a suitable living environment for chickens. Key features include:

Temperature control: The environmental control equipment automatically regulates the temperature in the chicken house to ensure that the chickens are in the appropriate temperature range in different seasons.

Ventilation systems: Equipment designs often include efficient ventilation systems that ensure the circulation of fresh air and reduce ammonia concentrations.

What can livi Machinery bring to you?

Pre-Sales Services:

- Professional Consultation: Our professional design team is ready to provide you with design solutions within 24 hours.

- Tailored Design Solutions: provides customized design solutions that optimize space, enhance workflow efficiency.

After-Sales Services:

- Installation Services:Installation drawings and site installation

- Transportation Services:livi Machinery will handle import and export problems for you.

- Maintenance and Technical Support:We’re here to assist you with technical inquiries, farming advice, and emergencies throughout the year.