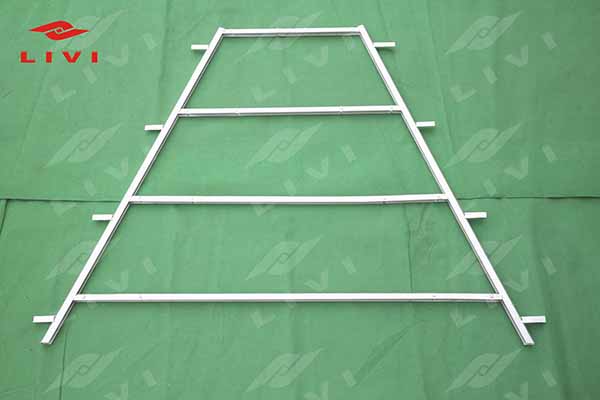

A Type brood Battery cage

Product: A-Type Brood BatteryCage

Application: Pullet Chickens

Anti-corrosion Treatment Process: Hot-dip Galvanized

Tiers: 3-4 Tiers

Raw Material: International Q235 Bridge Steel

Capacity: 144-216 Birds/Set

Lifespan: 15-20 Years

Product Introduction

The A-Type Brood Battery Cage is a purpose-built system tailored for the efficient management of chicks during the brooding phase. It features a horizontal, rectangular design with individual compartments to house small groups of chicks. The cage provides a controlled and secure environment for the chicks, facilitating optimal temperature regulation, easy access to feed and water, and efficient waste management. The A-Type Brood Battery Cage is designed to promote the healthy development of chicks, ensuring a strong start in their growth journey.

The specific introduction of A type brood battery cage is as follows:

| Brief Details | |

| Material | International Q235 steel. |

| Anti-corrosion Treatment Process | Hot-dip Galvanized, Aluminum-Zinc Alloy |

| Lifespan | 15 – 20 Years |

| Certificate | ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC |

| Production Lead Time | Depending on the order quantity. Normally about 10 days for 20ft container, 15 days for a 40ft container. |

| Supply Ability | 10000 Set/Month |

| Packing Method | Normal export packing. 20ft / 40ft container. |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF |

Specification of A type brood battery cage

The commonly used specifications of A type brood battery cage mainly have three layers and four layers.

| A-type Brood Battery Cage Specification | |||||

| Type | Weight | Model | Birds Qty/Door | Birds Qty/Unit | Specification |

| A-Type | 54KG | 3-Tier 3-Door | 8-12 pcs | 144-216 pcs | 1950mm*500mm*350mm |

| 72KG | 4-Tier 3-Door | 8-12 pcs | 192-288 pcs | 1950mm*500mm*350mm | |

Characteristics of A type brood battery cage

Sturdy Construction:

These cages are constructed with durability in mind, ensuring a robust and secure environment for the chicks. Sturdy materials contribute to the long lifespan of the brood battery cage.

Customizable Configurations:

A-Type Brood Battery Cages often come with customizable configurations to meet the specific needs of the poultry farm. Farmers can choose layouts based on the number of chicks and available space.

Facilitates Monitoring and Management:

The cage design allows for easy monitoring and management of chicks. Farmers can observe the chicks closely, perform health checks, and ensure that optimal conditions are maintained.

Promotes Uniform Growth:

The individual compartments contribute to uniform growth among chicks by preventing overcrowding and competition for resources. This promotes a healthier and more consistent flock.

Basic chicken equipment

chicken cage frame

Solid construction: A strong material, such as steel. Ensure that the system is structurally.

Hierarchical design: Multi-layer design, forming an A-shaped structure, so that the chickens can live in order at different levels.

chicken cage net

Material: High quality metal material to ensure durability and corrosion resistance.

Grid design: Ensure ventilation and observation.

chicken throuhg

Location design: The food tank ensure that each chicken can easily get enough feed.

Material health: The trough is made of easy to clean and corrosion-resistant materials to ensure the health and safety of feed

chicken drinking line

Automatic water supply: It ensures that the chickens have access to clean and fresh water at all times.

Leak-proof design: Plumbing systems are often leak-proof in design, reducing water waste.

Automated chicken raising equipment

Chicken manure cleaning equipment

Automated manure removal equipment is an important tool for maintaining chicken coop hygiene. Key features include:

Automatic cleaning: Cleaning equipment can automatically clean, effectively reduce the impact of feces on the health of chickens.

Efficient cleaning: The equipment design can efficiently clean up the feces in the chicken house, reduce labor costs, and improve the cleaning effect.

Chicken Feeding Equipment

The introduction of automated feeding equipment makes the feed delivery more precise and orderly. Key features include:

Automatic feeding: The feeding equipment can automatically feed according to the preset time and amount to ensure that the chickens get adequate nutrition.

Uniform distribution: The feeders are designed to achieve an even distribution of feed, avoiding waste and ensuring that each chicken gets enough feed.

Environmental control equipment

Automated environmental control equipment helps to provide a suitable living environment for chickens. Key features include:

Temperature control: The environmental control equipment automatically regulates the temperature in the chicken house to ensure that the chickens are in the appropriate temperature range in different seasons.

Ventilation systems: Equipment designs often include efficient ventilation systems that ensure the circulation of fresh air and reduce ammonia concentrations.

What can livi Machinery bring to you?

Pre-Sales Services:

- Professional Consultation: Our professional design team is ready to provide you with design solutions within 24 hours.

- Tailored Design Solutions: provides customized design solutions that optimize space, enhance workflow efficiency.

After-Sales Services:

- Installation Services:Installation drawings and site installation

- Transportation Services:livi Machinery will handle import and export problems for you.

- Maintenance and Technical Support:We’re here to assist you with technical inquiries, farming advice, and emergencies throughout the year.