In designing an efficient poultry farming system, Livi Machinery has crafted a comprehensive solution tailored for a poultry farmer seeking to house 45,000 layers in automatic poultry cages. This solution integrates advanced automation technologies to streamline operations and maximize productivity.

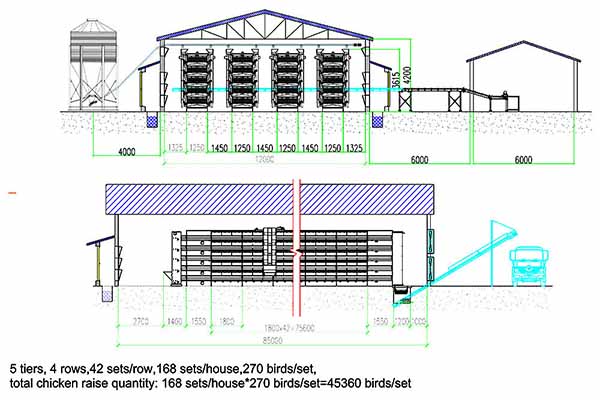

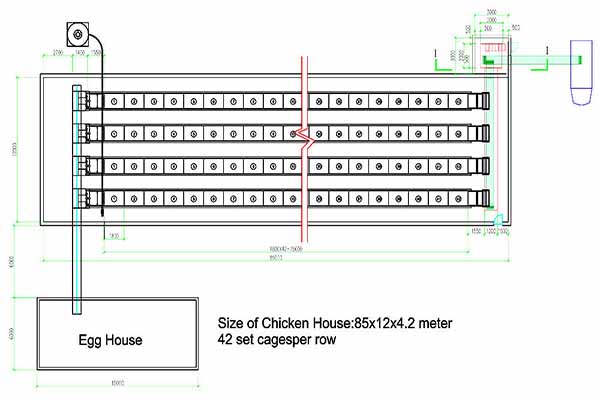

Chicken House Dimensions:

The chicken house measures 85 meters in length, 12 meters in width, and 4.2 meters in height.

The egg depot spans 15 meters by 6 meters.

Poultry Cage Specifications:

Utilization of H-type egg chicken cages, comprising 5 tiers per set.

Each set of H-type egg chicken cages accommodates 270 layers.

The dimensions of the H-type 5-tier egg chicken cage are 1800 by 1250 by 3610 millimeters.

A total of 168 sets of H-type egg chicken cages are installed within the chicken house, allowing for the housing of 45,360 layers.

The cages are arranged in 4 rows, with each row containing 42 sets of H-type egg chicken cages.

Automation Features

Full automatic poultry equipment is implemented within the chicken house, encompassing automatic feeding, egg collection, and waste removal systems.

The automatic egg collection system is directly linked to the adjacent egg depot, eliminating the need for manual labor in egg collection.

The automated waste removal system includes a transverse slanted waste conveyor connected to the exterior of the chicken house. It facilitate the direct transportation of chicken manure outside the chicken house.

This integrated solution by Livi Machinery epitomizes modern poultry farming practices. It leverage automatic poultry equipment to enhance efficiency, hygiene, and overall poultry welfare. By embracing such technological advancements, poultry farmers can achieve higher levels of productivity while minimizing labor-intensive tasks, thereby optimizing their operations for sustainable success.

Want a free chicken design? Leave us a message.