In modern poultry farming, maximizing efficiency while ensuring the welfare of the birds is paramount. One such innovative solution comes from Livi Machinery, who recently designed a poultry battery cage system tailored for a poultry farmer housing 30,000 egg-laying hens.

Design Overview

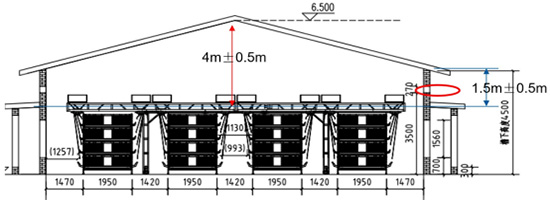

The chicken house spans an impressive 70 meters in length, 15 meters in width, and stands 4.5 meters tall. Utilizing the H-type layer cage system, Livi Machinery has optimized space and functionality to accommodate the substantial poultry population efficiently.

H-Type Layer Cage Configuration

To house the 30,000 layers, 220 sets of H-type layer cages are required. These poultry battery cage system are strategically arranged within the chicken house in four rows, with each row comprising 55 sets of cages. The spacing between each row of cages is approximately 1.4 meters, ensuring adequate airflow and ease of management.

Automation Integration

Automation plays a crucial role in the efficient operation of the chicken battery cage system. Livi Machinery has incorporated a range of automated equipment within the chicken house, including feeding systems, egg collection systems, and manure removal systems. These automated processes not only streamline daily operations but also contribute to the overall health and hygiene of the poultry environment.

Environmental Control System

Maintaining optimal environmental conditions is essential for the well-being and productivity of the laying hens. To achieve this, environmental control equipment is installed both inside and outside the chicken house. Outside, ventilation systems consisting of fans and water curtains are positioned approximately 1.5 meters above ground level. Additionally, side vents are installed above the water curtains at a height of approximately 27 centimeters, facilitating proper air circulation.

Conclusion

Livi Machinery’s innovative design for a 30,000-layer poultry battery cage system exemplifies efficiency, functionality, and animal welfare. By leveraging advanced cage configurations, automation technology, and environmental control systems, poultry farmers can optimize production while ensuring the comfort and health of their flocks. As the demand for sustainable and high-yield poultry farming practices continues to rise, solutions like these pave the way for a more efficient and responsible industry.

If you would like to design a breeding solution for your chicken house, please leave us a message.