Livi Machinery offers an efficient and automated solution Of 30000 Chickens In Automatic Poultry Cages, tailored to the dimensions of the layer house and the farmer’s requirements. Below are the key features and specifications of the layer house design:

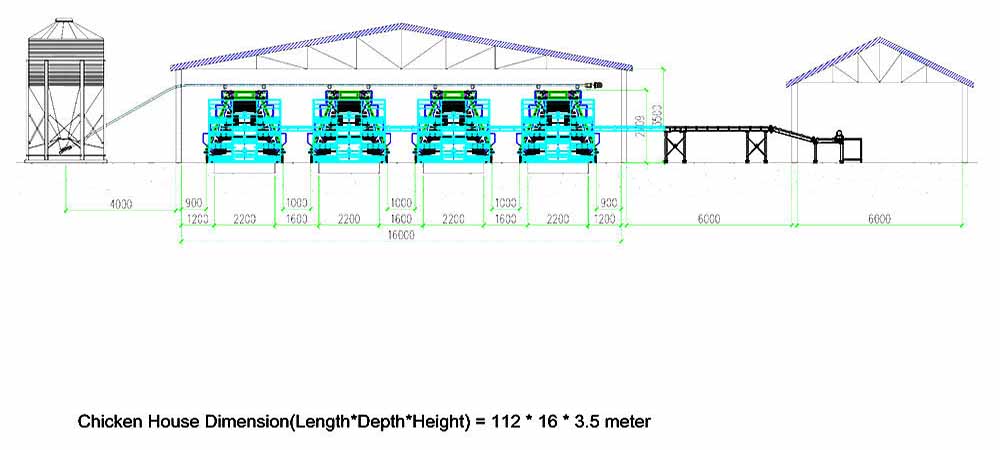

Poultry House Specifications

Dimensions: 112m (L) x 16m (W) x 3.5m (H)

Capacity: 30,080 laying hens

Design Considerations:

Front end: 2m space reserved for activity.

Rear end: 2m space reserved for a manure collection pit.

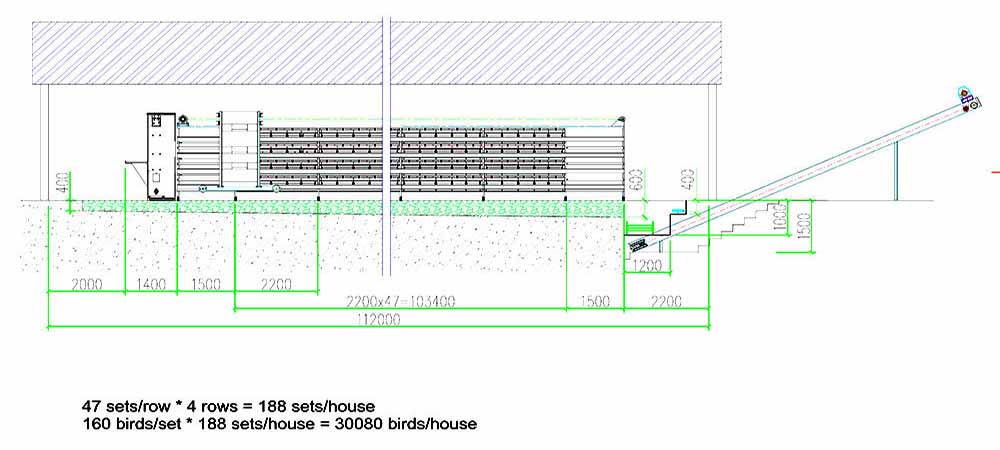

A-Type 4-Tiers Egg Chicken Cages

Specifications:

Size: 1950mm x 450mm x 410mm per unit

Tiers: 4 tiers per unit

Capacity: 160 chickens per unit

Placement:

Rows: 4 rows

Units per Row: 47 units

Total Units: 188 units

Total Capacity: 160 chickens per unit x 188 units = 30,080 chickens

Automatic Chicken Raising Equipment Overview

Automated Egg Collection System:

Directly connects to the egg storage room (10m x 6m x 3.5m).

Facilitates easy packaging and classification of eggs for sale.

Automated Feeding System:

Connects to external feed silos.

Ensures consistent and efficient feed distribution to all hens.

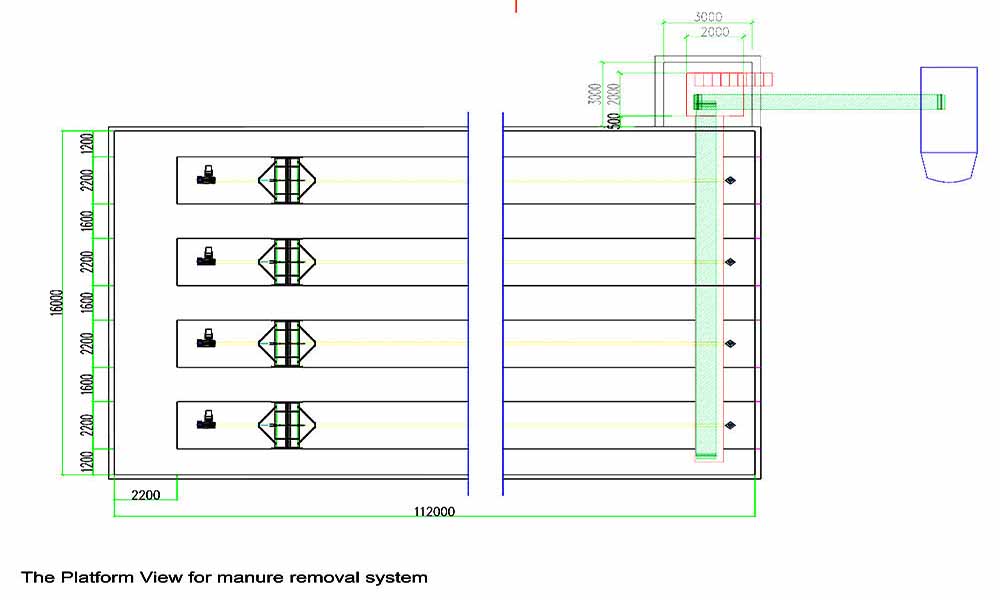

Automated Manure Removal System:

Manure collection pits beneath the cages.

Scraper-type manure removal system transports manure to the end of the poultry house.

Conveyors transport manure out of the house for efficient waste management.

Summary of Equipment

A-Type 4-Tiers Automatic Poultry Cages

Automated Egg Collection Equipment

Automated Feeding Equipment

Automated Manure Removal Equipment

Livi Machinery’s layer house design optimizes space and ensures a highly automated and efficient environment for poultry farming, meeting the target of housing 30,000 laying hens. This setup minimizes labor, enhances productivity, and provides a streamlined approach to egg production and waste management.

If you would like our chicken design, please leave us a message.