Raising broilers in large numbers requires meticulous planning, efficient systems, and the right equipment. Among the many methods of poultry farming, utilizing a battery cage system has emerged as a preferred choice for many poultry farmers, especially when aiming to rear a significant number of broilers like 30,000 in a single chicken house. Livi Machinery offers a Solution Of 30000 layers With Battery Cage for chicken farmers.

1. The Challenge of 30000 layers raising

When considering raising 30,000 layers, the challenges are manifold. Space, feeding efficiency, waste management, and overall flock health become critical concerns. Traditional free-range methods might not be feasible due to space constraints and the need for more intensive management practices.

2. Introducing the Battery Cage System

Livi Machinery has designed a chicken raising Solution Of 30000 layers With Battery Cage for chicken farmers. Battery cage systems offer a solution tailored for high-density farming. By vertically stacking cages, these systems optimize space utilization, allowing for a higher number of layers to be housed in a compact area without compromising their well-being.

3. Advantages of layers with Battery Cage

- Space Optimization: By going vertical, the system maximizes floor space, ensuring that each layer has adequate room to grow and move.

- Efficient Feeding and Waste Management: Battery cages are designed for efficient feeding, ensuring that every layer gets the required nutrients. Additionally, waste management becomes more streamlined, aiding in maintaining a hygienic environment.

- Disease Control: With reduced direct contact between layers, the risk of disease spread diminishes, enhancing overall flock health.

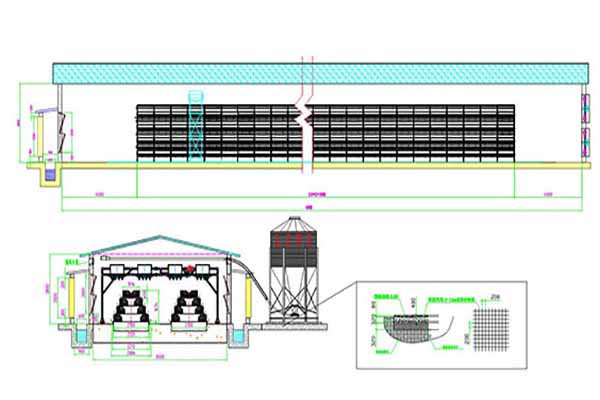

4. Solution of 30000 layers with battery cage

- 30000 Layers

- Two chicken house, 15000 layers/1 house

- 4 ties A type layer battery cage

- 47 sets/row, 2 row/1 house

- Totally 188 sets of battery cage

- Two gantry feeders

- Two flat belt cleaning machines

- Tower

- environmental control system

5. Livi Machinery’s Customized Solutions

The Livi Machinery’s customized solution of 30000 layers With Battery Cage provided the farmer with the direction of the main chicken business. Understanding the intricacies of poultry farming and the unique challenges posed by raising 30,000 layers, Livi Machinery has designed specialized battery cage systems tailored for such large-scale operations. Their expertise lies not just in providing equipment but in offering holistic solutions. From the layout of the chicken house to the integration of feeding and watering systems, Livi ensures that every aspect is optimized for efficiency and productivity.

6. Conclusion

Raising 30,000 layers is no small feat, but with the right solutions in place, it becomes a manageable and profitable venture. The battery cage system, particularly when designed and implemented by industry leaders like Livi Machinery, offers a pathway to achieve scale without compromising on quality or animal welfare. As the demand for poultry products continues to grow, such innovative solutions pave the way for sustainable and efficient poultry farming.