In the realm of poultry farming, efficiency and productivity are paramount. When faced with the challenge of accommodating 10,000 layer chickens, one farm owner in need of a comprehensive Solution Of 10000 Chickens Layer Battery Cage turned to Livi Machinery. With expertise in providing innovative poultry farming equipment, Livi Machinery crafted a tailored design to meet the client’s needs.

A-Type 4-Tier Layer Battery Cage

Central to the design solution provided by Livi Machinery is the utilization of A-Type 4-tier chicken cage. These cages, with dimensions of 1950*450*410mm, offer optimal space utilization and comfort for the layer chickens. With a requirement of 66 sets of A-Type 4-tiers chicken cage, the design ensures sufficient accommodation for the entire flock.

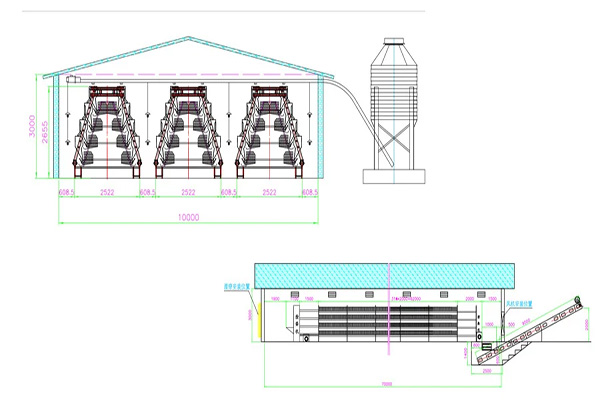

Optimized Chicken House Dimensions

To accommodate the 10,000 layer chickens, the chicken house dimensions were carefully calculated. Spanning an area of 50*10*3 meters, the chicken house provides ample space for housing the layer battery cages while allowing for ease of movement and management within the facility.

Automatic Poultry Cage Enhancements

Livi Machinery’s solution goes beyond the provision of layer battery cages. It encompasses a range of automated poultry farming equipment to streamline operations and maximize efficiency. The inclusion of a gantry feeding machine, flat belt manure removal system, egg collection equipment, feed tower, and chicken manure conveyor ensures seamless management of the layer flock.

Efficiency and Convenience

By implementing Livi Machinery’s design solution, the farm owner gains access to a highly efficient and convenient automatic poultry cage system. The automated feeding and manure removal systems reduce labor costs and minimize manual intervention, allowing for more efficient allocation of resources and time.

Promoting Animal Welfare

While optimizing productivity and efficiency, Livi Machinery’s solution also prioritizes animal welfare. The design ensures that the layer chickens have access to clean and comfortable living conditions, promoting their health and well-being. Additionally, the automatic poultry cage systems help maintain optimal environmental conditions within the chicken house, further enhancing the welfare of the flock.

Conclusion

Livi Machinery’s design solution for accommodating 10,000 layer chickens exemplifies innovation and efficiency in poultry farming. By integrating A-Type 4-tiers chicken cage with advanced automation equipment, the farm owner can effectively manage a large-scale layer operation while promoting animal welfare and maximizing productivity. With Livi Machinery’s expertise, the client is poised for success in the dynamic poultry farming industry.

Contact us for a free chicken raising design and automatic poultry cage quotation.