Livi Machinery provides chicken farmers with layer battery cage system that can raise 20,000 laying hens in a 90*13*3.2M chicken house.

1. Chicken House Planning:

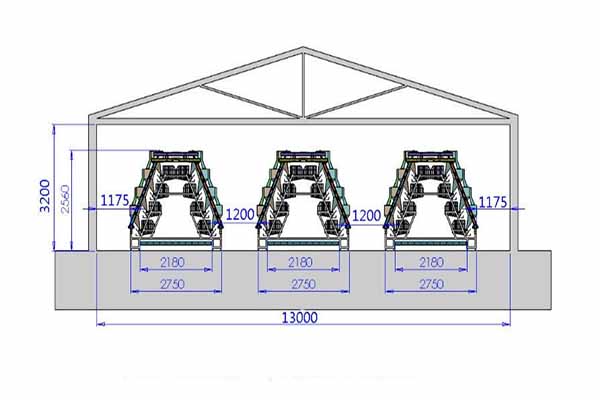

- Dimensions: 90*13*3.2 meters

- Facilities: The Chicken house is equipped with advanced automatic poultry equipment, including automatic feeding systems, automated manure removal systems, and automated egg collection systems.

2. Layer Cage Selection:

- Type: A-type layer cage

- Specifications: 1950*450*410mm

- Capacity per Unit: Each cage can house 160 egg-laying chickens

- Total Requirement: 126 sets of A-type layer cage

- Layout: The A type layer cages are arranged in three rows within the barn, with 42 sets per row.

3. Automatic Poultry Equipment

- Automatic Feeding System: Dispenses feed at regular intervals to ensure balanced nutrition for the flock, thereby enhancing productivity.

- Automatic Manure Removal System: Regularly removes excreta from the barn, maintaining a clean environment and reducing the spread of diseases.

- Automatic Egg Collection System: Automatically collects eggs to prevent breakage and waste, thereby increasing profitability and efficiency.

Through the above planning and layer battery cage system configuration, efficient management and rearing of 20,000 egg-laying chickens can be achieved, leading to improved farming efficiency and economic benefits.

If you need layer battery cage system or a free chicken design, please leave us a message.