Livi Machinery, a leading manufacturer of poultry farming equipment, recently worked with a client in Kenya to supply pullets battery cage systems for raising 50,000 chickens. This project showcases the growing demand for efficient and sustainable poultry farming solutions in Kenya and highlights the importance of advanced equipment for maximizing productivity.

1. Client’s Needs: A Solution for Raising 50,000 Pullets in Kenya

Our client from Kenya was looking for an efficient and scalable poultry farming system to raise 50,000 pullets. With the rising demand for poultry products in the region, the client wanted a solution that would ensure high productivity, ease of management, and the ability to handle a large number of chickens with minimal labor costs. The challenge was to design a system that would not only accommodate 50,000 pullets but also offer long-term sustainability and profitability.

After discussing the client’s requirements, we proposed the installation of pullets battery cage systems—a proven solution for maximizing space, minimizing labor, and improving chicken health and productivity.

2. Designing the Poultry Battery Cages for 50000 Chickens

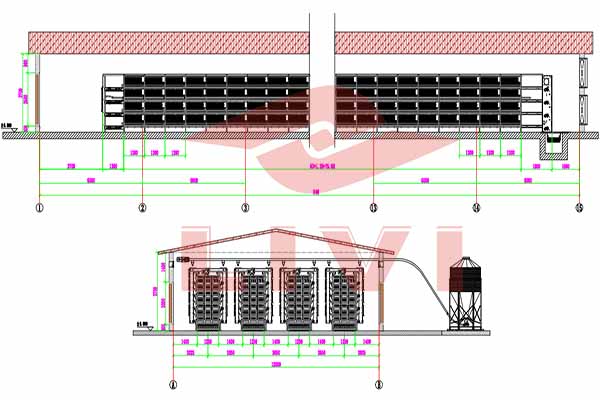

For a farm with 50,000 chickens, it was crucial to have a carefully planned layout to maximize space usage and ensure efficient operation. Our design included multiple tiers of battery cages for pullet farming in Kenya, ensuring the chickens would have enough space to grow while keeping the facility compact and manageable.

The design was based on an H-type cage system, which is ideal for pullet farming. Each cage tier has a sufficient number of birds while still maintaining high standards of hygiene and chicken welfare. The layout was optimized to allow for easy access for feeding, watering, egg collection, and waste management, all while keeping the cost of labor low.

50000 Pullets Chicken House Design

3. H-Type Pullets Battery Cage Systems: Specifications and Advantages

The H-type pullets battery cage system we provided for the client includes a range of advanced features:

- Space Efficiency: The vertical design of the battery cages for pullet farming allows for maximum utilization of space, accommodating large numbers of chickens in a small area.

- Automatic Systems: The system includes automated feeding, drinking, and egg collection systems, reducing the need for manual labor and increasing operational efficiency.

- High-Quality Materials: The cages are made of durable materials such as galvanized steel, ensuring a long lifespan and minimal maintenance.

- Optimized Ventilation and Lighting: Each cage is designed for optimal airflow and light distribution, improving the health and growth rate of the pullets.

- Easy Maintenance: The modular design makes it easier to maintain, clean, and replace parts, reducing downtime and operational costs.

These features make the pullets battery cage systems an ideal choice for large-scale poultry farming operations in Kenya, where space and labor costs are significant concerns.

4. Efficient Poultry Farming and Long-Term Profitability

By implementing our battery cages for pullet farming in Kenya, the client can expect higher efficiency in raising 50,000 pullets. The system ensures that the chickens are well-fed, healthy, and have enough space to grow, which leads to higher survival rates and better egg production.

In addition, the automated systems reduce the amount of labor required, cutting down on costs and improving overall profitability. With proper management, the pullets battery cage systems will provide long-term, sustainable returns by increasing the farm’s production capacity while keeping operational costs low.

Pullets Battery Cage Systems For 50,000 Chickens In Kenya

5. Why Choose Livi Machinery?

Livi Machinery is known for its commitment to quality and innovation in poultry farming equipment. Here are some reasons why our clients choose us for their poultry farming needs:

- Proven Track Record: We have successfully completed numerous large-scale projects, including those involving pullets battery cage systems for farms with tens of thousands of chickens.

- Custom Solutions: We provide tailored solutions to meet the specific needs of each client, ensuring the design is optimized for their farm’s size and requirements.

- Reliable Support: From installation to after-sales service, we provide ongoing support to ensure that our equipment performs at its best throughout its lifespan.

- Sustainability: Our systems are designed to be energy-efficient and environmentally friendly, ensuring long-term sustainability for our clients.

For the client in Kenya, choosing Livi Machinery meant investing in a reliable, high-performance system that would support their poultry farming business for years to come.

6. Get Started Today: Contact Us to Launch Your Poultry Farming Business

Are you interested in starting or upgrading your poultry farm with pullets battery cage systems? Livi Machinery is here to help. With our expertise in designing efficient, high-capacity poultry farming systems, we can provide the perfect solution for your needs.

Contact us today to learn more about how our poultry battery cages for 50000 chickens can help you create a profitable and sustainable poultry farming business in Kenya or elsewhere.

By choosing Livi Machinery, you are investing in a system that maximizes space, reduces labor, and Improves breeding efficiency—ensuring the long-term success of your poultry farm.