Poultry farming in Zimbabwe, particularly broiler production, is an increasingly popular and lucrative venture. However, when deciding to raise 10,000 broilers, one of the first considerations is how much space is required. The answer can vary depending on the type of farming system you choose. In this article, we will explore the two main poultry farming systems—broiler cage farming and broiler flooring farming—and their space requirements, equipment needs, advantages, and potential economic benefits for 10000 broiler in Zimbabwe. We will also introduce Livi Machinery as a poultry farming equipment supplier, providing solutions for both cage-based and floor-based systems, to help you make an informed decision for your poultry farm.

1. Introduction to Poultry Farming in Zimbabwe

Poultry farming, particularly broiler production, plays a significant role in Zimbabwe’s agricultural sector. Broilers are grown for meat production and are known for their rapid growth rate, making them a highly efficient livestock choice for farmers. However, establishing a successful broiler farm requires careful planning, especially when it comes to space allocation and equipment selection.

Whether you are setting up a commercial broiler farm or expanding an existing one, understanding how much space you need for 10,000 broilers is crucial. The space requirement will differ based on whether you use a broiler cage system or a poultry flooring system. Each system comes with its own set of challenges and benefits, which we will discuss in detail in the following sections.

How Much Space Do You Need for 10000 Broilers in Zimbabwe?

2. How Much Space Do You Need for 10000 Broilers in Zimbabwe With Poultry Cage System?

Broiler Cage System Space Requirements

For cage-based poultry farming, 10,000 broilers typically require approximately 400 square meters. This system is designed to maximize space efficiency, allowing farmers to house a large number of birds in a relatively compact area.

In a cage system, broilers are kept in specially designed broiler cage system, which are stacked in multiple tiers. Each cage provides enough room for the birds to move around and access food and water. The space needed for 10,000 birds will depend on the size of the cages and the number of tiers used, but the general rule is that each broiler needs between 300 to 350 square centimeters of space in a cage.

The broiler cage system are a critical piece of poultry farming equipment in this system. These cages are designed to increase stocking density while still maintaining adequate space for each bird, improving production efficiency.

Equipment for Broiler Battery Cage System

To ensure the smooth running of a cage-based system, you will need a variety of poultry farming equipment:

- Broiler Battery Cages: These cages are designed for high-density farming and can be equipped with automatic feeders and drinkers. They help reduce feed wastage and ensure that each bird receives the right amount of nutrients.

- Automated Feeding Systems: A broiler feeding equipment system is essential to ensure uniform distribution of feed, reducing labor costs and preventing feed wastage. Automated systems allow for precise control of feed quantity, promoting better growth rates.

- Automated Drinking Systems: With an automatic water line system, each bird has constant access to clean water, which is essential for growth. Automated systems help to reduce labor input and maintain hygiene.

- Manure Removal Systems: Automatic manure removal systems can help maintain a clean and healthy environment for your birds. These systems automatically remove waste, reducing the risk of disease and keeping the cages clean with minimal labor input.

Advantages and Disadvantages of Broiler Cage Farming

Advantages:

- Space Efficiency: The broiler cage farming system utilizes space efficiently, allowing for high-density housing of broilers in a smaller area.

- Increased Production Efficiency: The use of automated systems for feeding, drinking, and manure removal improves the overall efficiency of the operation.

- Reduced Disease Risk: Since the broilers are housed in individual cages, it is easier to monitor their health and prevent disease spread.

Disadvantages:

- High Initial Investment: The cost of purchasing and installing automated poultry farming equipment, such as broiler battery cages and automated feeders, can be significant.

- Welfare Concerns: Some argue that cage-based systems, especially in high-density setups, do not allow for sufficient natural behavior, leading to stress and reduced welfare for the birds.

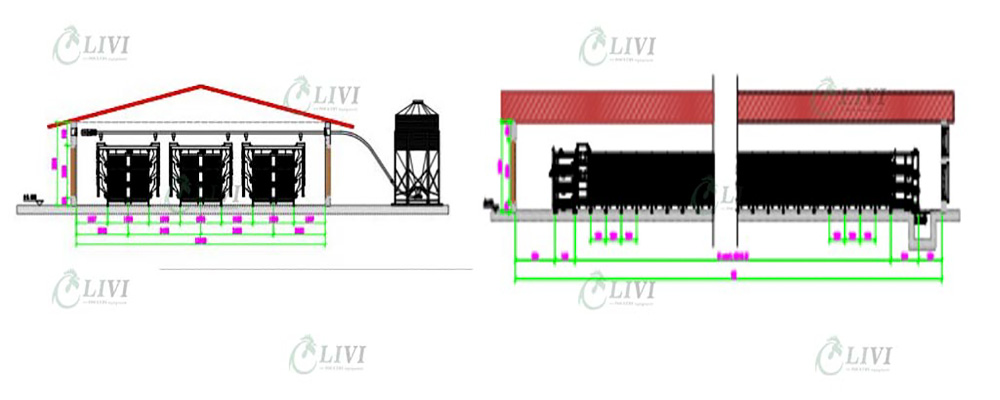

10000 Broilers Poultry House Design With Chicken Battery Cage System

Chicken house size: 40*12M

Location: Zimbabwe

Breeding capacity: 10,200 broilers

broilers Chicken cage specifications: 1050mm800mm*420mm

Chicken cage arrangement: 3 rows, each row 25 sets of cage

Automatic chicken equipment: automatic feeding equipment, automatic cleaning equipment, automatic drinking water equipment, environmental control equipment and so on

In this case, the broiler battery cages are equipped with automatic feeding and water systems, allowing for efficient space usage and minimal labor. The cages are stacked in three tiers, with each tier housing 3,000 broilers, giving the farm an optimal use of vertical space. The farm also implemented an automatic manure removal system to maintain cleanliness and reduce the need for manual labor. The system is designed for ease of maintenance and reduces the risk of disease spread by keeping the environment dry and sanitary. This cage-based farming approach has allowed the farm to achieve high production rates while maintaining low operational costs due to its compact design and automated systems.

3. How Much Space Do You Need for 10000 Broilers in Zimbabwe With Poultry Flooring System?

Broiler Flooring System Space Requirements

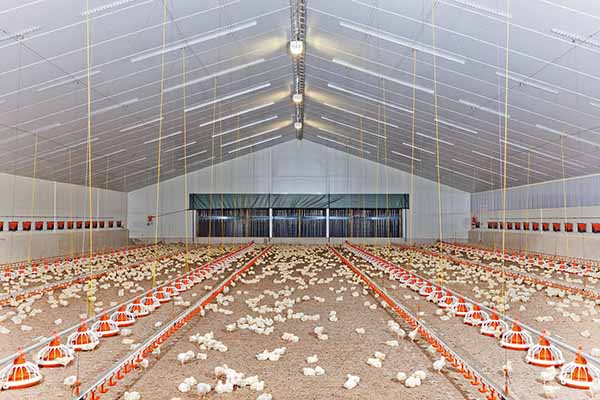

For Broiler Flooring System, the space requirement for 10,000 broilers is typically around 750 square meters. This system allows broilers to move freely on the floor of the poultry house, which can help improve their overall health and welfare.

In a poultry flooring system, broilers are raised in a more natural environment where they can walk, stretch their wings, and engage in natural behaviors like pecking and scratching. The larger space requirement for floor-based farming is due to the need to provide enough room for the birds to roam freely while maintaining an optimal stocking density.

Equipment for Poultry Flooring System

The Poultry Flooring system requires a different set of poultry farming equipment:

- Automatic Feeding Lines: An automatic feeding system is still essential in this setup to ensure that all birds are fed evenly. Floor-based feeding lines can be installed to provide constant access to fresh feed for the broilers.

- Automatic Drinking Systems: Similar to cage-based systems, automatic water lines are important to ensure that broilers have easy access to water. These systems help reduce labor input while ensuring that all birds are hydrated.

- Bedding and Flooring: Broiler flooring equipment such as litter and bedding is essential to create a comfortable and clean environment for the birds. The flooring must be designed to absorb moisture and waste to prevent health issues such as footpad dermatitis.

- Ventilation and Temperature Control: Proper environmental control systems, including ventilation and heating, are crucial in floor-based systems. These systems ensure that the poultry house remains at an optimal temperature and humidity, promoting healthy growth for the broilers.

Advantages and Disadvantages of Broiler Floor-Based Farming

Advantages:

- Animal Welfare: Floor-based farming allows broilers to move freely, engage in natural behaviors, and have more space to grow. It lead to potentially healthier birds and better-quality meat.

- Lower Initial Investment: Compared to cage systems, the initial investment for floor-based poultry equipment may be lower, as it doesn’t require complex cages or automated systems.

Disadvantages:

- Lower Space Efficiency: The larger space requirement for floor-based farming can lead to higher land and building costs.

- Labor Intensive: Although automated feeding and drinking systems can reduce labor needs, floor-based systems still require significant labor for litter management, cleaning, and monitoring bird health.

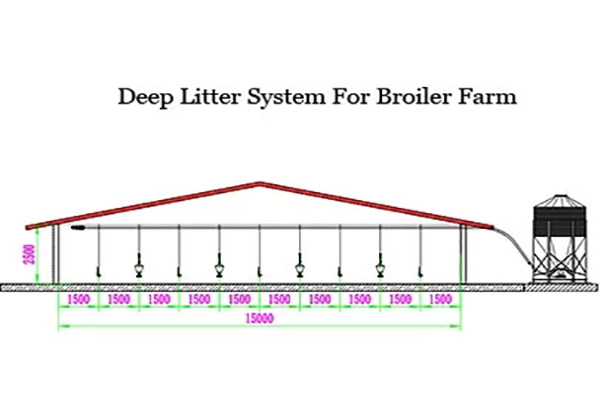

10000 Broilers Poultry House Design With Chicken Flooring System

Chicken house size: 75*10M

Location: Zimbabwe

Breeding capacity: 10,000 broilers

Ground breeding equipment: 5 automatic water lines, 4 automatic feed lines, environmental control system

The floor is covered with a deep litter bedding system that absorbs waste and moisture, helping to maintain hygiene. The farm also implemented a ventilation system to regulate temperature and humidity. It ensure a healthy and comfortable environment for the broilers. This system helps in maintaining a uniform temperature across the larger space, which is especially important for the health of the birds. Despite the higher land and operational costs compared to a cage-based system, the floor-based approach has been successful in producing high-quality broilers with excellent welfare standards. It contribute to better growth rates and lower mortality.

4. Broiler Cage Farming vs. Poultry Floor Farming: Space Efficiency and Comparison

When comparing the space efficiency of broiler cage farming and poultry flooring farming, there is a significant difference. Cage-based systems allow for higher stocking density, which means fewer square meters are needed to house 10000 broilers in Zimbabwe. In contrast, floor-based systems require more space to accommodate the same number of birds, which might increase costs if land is limited.

However, Broiler flooring system may be more suited for those who prioritize animal welfare and natural behaviors, as it provides broilers with more space to move and interact with one another. On the other hand, cage-based farming is ideal for commercial operations focused on maximizing space utilization and productivity.

Broiler Battery Cages VS. Poultry Flooring System

5. Livi Machinery’s Poultry Equipment Recommendations

At Livi Machinery, we understand the importance of having the right equipment to ensure the success of your poultry farm. Whether you choose broiler cage system or poultry flooring system. We offer a comprehensive range of high-quality poultry farming equipment designed to optimize your production and reduce labor costs.

Broiler Cage Farming Equipment

Livi Machinery offers a wide range of broiler battery cages that are designed to maximize space efficiency and productivity. Our broiler battery cages are equipped with automatic feeding systems, automatic watering systems, and automatic manure removal systems. It ensure that your farm runs smoothly with minimal labor input.

Poultry Flooring Equipment

For those opting for floor-based farming, Livi Machinery provides automatic feeding lines and automatic water lines to ensure that your birds have constant access to food and water. Additionally, we offer broiler flooring equipment designed to promote cleanliness and comfort for your broilers, as well as ventilation systems to maintain optimal environmental conditions.

Customized Solutions

We offer customized solutions tailored to your specific farming needs. Whether you’re managing a small farm or a large-scale commercial operation. We can provide the equipment and support necessary to maximize efficiency and profitability.

6. Conclusion

In conclusion, the amount of space you need for 10000 broilers in Zimbabwe depends largely on the type of farming system you choose. Broiler Cage System offer higher space efficiency and are ideal for large-scale, commercial operations, while Poultry Flooring System provide more natural living conditions for the birds but require more space. Both systems come with their own advantages and challenges, but with the right equipment, both can be highly successful.

At Livi Machinery, we provide a wide range of poultry farming equipment, including broiler battery cages, automated feeding systems, and flooring solutions, to help you optimize your poultry farming operations. Whether you are looking to set up a cage-based system or a floor-based system, we have the equipment and expertise to support your farming success.