Automatic Chicken Manure Cleaning System

Chicken manure cleaning system has important application value in poultry farming, which improve the efficiency of breeding.

Features: High efficiency

Long service life

Strong and durable

corrosion resistant

Product Introduction

The Automatic Chicken Manure Cleaning System is a state-of-the-art solution designed to streamline and automate the process of removing chicken manure in poultry farms. This system is available in various configurations, with the two main types being the belt-type system and the scraper-type system.

Components of Chicken Manure Cleaning System

The system comprises two main components, each tailored to specific farm requirements:

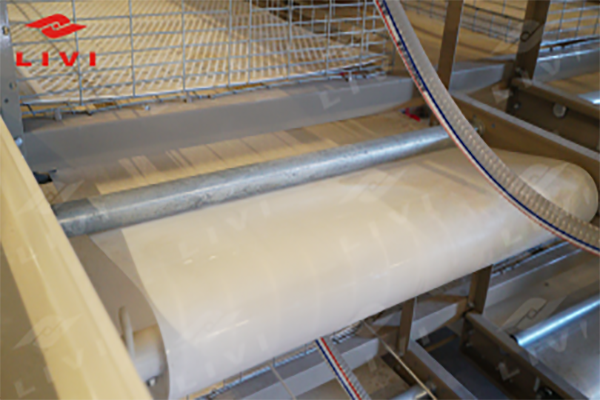

Belt-Type Manure Removal System

- Utilizes a conveyor belt to transport manure out of the poultry house.

- Operates continuously, ensuring a consistent removal of waste.

- Ideal for large-scale poultry farms with a high stocking density.

The belt-type cleaning system comprises essential components such as:

- Conveyor Belt: This robust belt is strategically placed beneath the chicken cages to collect and transport the manure to a designated location.

- Motor and Control Unit: The motor powers the conveyor belt, and the control unit ensures precise and automated operation.

Scraper-Type Manure Removal System:

- Employs a scraping mechanism to collect and remove manure.

- Suitable for farms with various cage configurations and layouts.

- Offers versatility in adapting to different poultry house designs.

The scraper-type cleaning system features key components, including:

- Scraper Blades: These durable blades scrape and collect the manure, transporting it along designated channels for removal.

- Motor and Control Unit: Similar to the belt-type system, the motor and control unit govern the automated functioning of the scraper-type system.

Role of Manure Cleaning Equipment in Poultry Farming

The Automatic Chicken Manure Cleaning System plays a pivotal role in poultry farming for several reasons:

- Disease Prevention: Efficient manure removal minimizes the risk of disease transmission among the flock, contributing to overall bird health.

- Improved Air Quality: By promptly removing manure, the system enhances air quality within the poultry house. It creat a more comfortable environment for the chickens.

- Labor Efficiency: Automated manure cleaning reduces the need for manual labor. It allow farm personnel to focus on other critical aspects of poultry management.

Relationship Between Manure Cleaning Equipment and Chicken Cages

The synergy between manure cleaning equipment and chicken cages is integral to a well-organized and hygienic poultry farm:

- Space Optimization: Both belt-type and scraper-type systems are designed to seamlessly integrate with various types of chicken cages, optimizing space within the poultry house.

- Minimized Contamination: The strategic placement of the manure cleaning system beneath the cages minimizes the risk of manure contamination, ensuring a clean and sanitary environment.

Conclusion

In conclusion, the Automatic Chicken Manure Cleaning System represents a significant leap forward in poultry farming technology. As an indispensable component in maintaining a healthy and efficient poultry farm, this system not only streamlines waste management but also contributes to disease prevention and labor efficiency. The careful integration of manure cleaning equipment with chicken cages reflects a holistic approach to modern poultry farming, emphasizing the importance of hygiene, bird health, and operational efficiency. With the evolution of such technologies, poultry farmers can navigate the challenges of waste management with ease, ensuring sustainable and prosperous farming practices.