Modern Layer Battery Cage System

Modern layer battery cage systems mainly includes A-type layer battery cage, H-type layer battery cage and automated chicken farming equipment.

The modernization of egg chicken farming represents a pivotal shift in the agricultural landscape, emphasizing the indispensable role of advanced farming equipment.

The modern equipment selected for breeding laying hens mainly includes A-type layer battery cage and H-type layer battery cage.

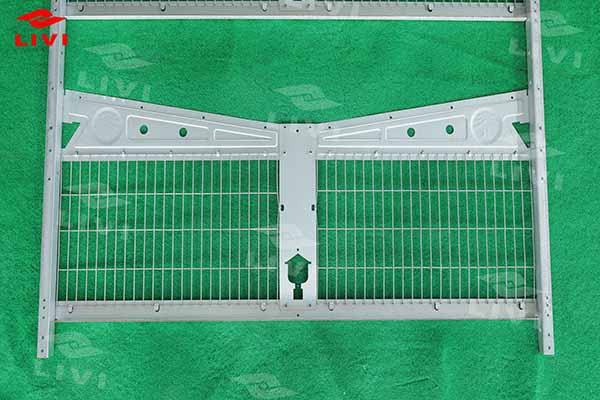

A-type Layer Battery Cage

A. Structural Specifications

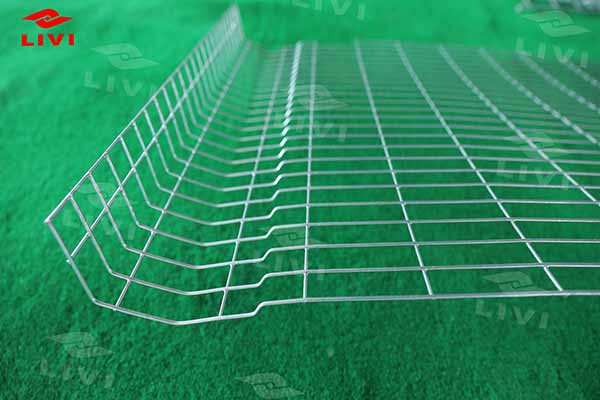

Material Composition: A-type layer battery cages are typically constructed using high-quality galvanized steel, ensuring durability and resistance to corrosion.

Chicken Cage Design: The cages feature a tiered structure, with multiple levels of compartments. Each compartment has a sloped floor for efficient egg rolling and collection.

Chicken Cage Dimensions: The standard A-type cage measures approximately 60cm in width, 40cm in height, and 50cm in depth. These dimensions are designed to provide sufficient space for the chickens while optimizing the use of available space in the chicken house.

B. Capacity and Scalability

Chicken Density: A-type cages can accommodate a high density of chickens per unit area, often ranging from 4 to 6 birds per compartment.

Adjustable Height: The cages are designed with adjustable heights, allowing for easy customization based on the size and breed of the chickens. This adaptability ensures optimal comfort for the birds.

Farm Scalability: A-type cages are suitable for both small-scale and large-scale poultry farms. The modular design enables easy expansion or contraction based on the evolving needs of the farm.

H-type Layer Battery Cage

A. Structural Specifications

Material Composition: Similar to A-type cages, H-type cages are crafted from durable galvanized steel to withstand the rigors of poultry farming.

Chicken Cage Design: H-type layer battery cages adopt a horizontal layout, with a tiered structure that provides ample space for chickens to move around. The design enhances air circulation within the cage, promoting a healthier environment.

Chicken Cage Dimensions: H-type cages typically have larger dimensions compared to A-type cages. The standard H-type cage might measure around 70cm in width, 50cm in height, and 60cm in depth.

B. Capacity and Scalability

Increased Space: H-type cages offer more floor space, accommodating a higher number of chickens per compartment. The increased space is beneficial for the birds’ physical well-being and reduces the risk of stress-related issues.

Suitable for Large Farms: Due to their spacious design, H-type cages are particularly well-suited for large-scale poultry farms where maximizing production efficiency is a priority.

Customization for Breeds: The horizontal layout of H-type cages allows for the accommodation of larger chicken breeds, making them versatile for farms that specialize in different types of layers.

Automated Chicken Farming Equipment

A. Egg Collection Equipment

The implementation of automated egg collection equipment marks a significant leap forward in efficiency. Equipped with intelligent recognition and sorting mechanisms, these automated chicken farming equipment systems not only increase the speed of egg harvesting but also substantially reduce manual labor costs. The seamless integration of technology ensures a more streamlined and hygienic egg collection process.

B. Waste Management Equipment

The adoption of intelligent cleaning systems has revolutionized waste management in chicken farming. Beyond the environmental benefits, these systems are energy-efficient and contribute to the overall cleanliness of the chicken house. Unpleasant odors, often associated with poultry farming, are mitigated, creating a more favorable environment for both chickens and farm workers.

C. Feeding Equipment

Precision feeding mechanisms embedded in automated feeding equipment allow for a quantified supply of feed. This not only ensures that chickens receive the necessary nutrients but also minimizes feed wastage. The automation of the feeding process contributes to the overall efficiency of chicken farming operations.

D. Environmental Control Equipment

Environmental control equipment encompasses the monitoring of temperature, humidity, and ventilation systems. These automated systems regulate lighting conditions, creating an optimal environment for the well-being of the chickens. This level of control ensures that the farming conditions closely mimic natural habitats, enhancing the health and productivity of the flock.

Leave us a message for our free modern layer battery cage systems!