Embarking on a Project Of 60000 Layers With Chicken Cage Price In Zimbabwe requires meticulous planning and the right poultry farming equipment. In this article, we will explore the details of the Project Of 60000 Layers With Chicken Cage Price In Zimbabwe.

Project Details

The project involves the establishment of a Project Of 60000 Layers With Chicken Cage Price In Zimbabwe. The scale of this endeavor necessitates strategic planning to ensure optimal space utilization, disease control, and efficient egg production.

Customer Requirements

Understanding the specific needs and requirements of the customer is paramount in designing a poultry farming project of this magnitude. Factors such as space constraints, budget considerations, and the desire for a sustainable and modern setup are taken into account.

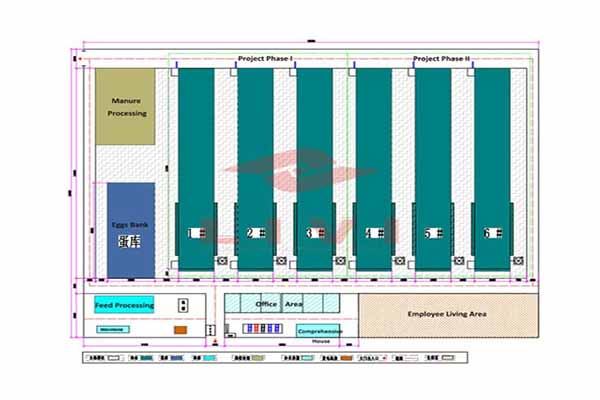

The Zimbabwean customer owns a 60M by 75M chicken farm with six identical sized chicken houses. The basic equipment in the chicken farm is complete, there are egg bank, chicken manure treatment area, office area and so on. He wants to raise 60,000 laying hens on the chicken farm.

Solution Of 60000 Layers With Chicken Cage

The design solution for the project involves the integration of state-of-the-art layer battery cages. These cages provide individual housing for each layer, optimizing space, facilitating disease control, and streamlining the egg collection process.

The interior design of the coop is as follows:

Breeding 60,000 laying hens In 6 coop, each coop raised 10,000 laying hens.

H-type layer cage is selected for large-scale breeding of laying hens.

The specification of H-type layer cage is 1200*650*480 (mm), 4 layers.

Each set of 4-layer H-type layer cage can raise 180 laying hens.

It takes 57 cages to raise 10,000 laying hens in a single coop. The 57 sets of H-type laying cages are placed in 2 rows in the hen house, with 28 sets of laying cages in each row.

A total of 342 H-type laying cage sets are required in the chicken farm.

Advantages of Layer Battery Cages in Zimbabwe

Space Utilization: Layer battery cages efficiently utilize space, allowing for the housing of a large number of layers within a confined area.

Disease Control: Individual housing minimizes the risk of disease spread among layers, contributing to a healthier flock.

Egg Collection Efficiency: The design of layer battery cages facilitates easy and efficient egg collection, reducing the risk of damage and ensuring cleanliness.

Customization: The design allows for customization based on the specific requirements of the poultry farm, providing flexibility in catering to customer needs.

Layer Battery Cage for sale to Zimbabwe by Livi Machinery

Livi Machinery, a leading provider of poultry farming equipment, extends its services to Zimbabwe by offering high-quality layer battery cages for sale. The company’s commitment to providing value for money and quality products sets it apart.

Affordability: Livi Machinery offers competitive chicken cage prices in Zimbabwe, ensuring that poultry farmers can invest in modern equipment without compromising their budget.

Comprehensive Support: Beyond the sale of layer battery cages, Livi Machinery provides comprehensive support. It include installation assistance, maintenance tips, and guidance on optimizing farm operations.

Quality Assurance: The company adheres to strict quality standards in the manufacturing process, guaranteeing durable and reliable equipment.

Customer Benefits in Zimbabwe

Zimbabwean customers benefit from Livi Machinery’s offerings in several ways:

- Efficiency: The use of modern layer battery cages enhances the efficiency of the poultry farm. It contribute to increased productivity and profitability.

- Sustainability: The design of the equipment aligns with sustainable farming practices, catering to the growing demand for environmentally conscious solutions.

- Cost-Effectiveness: The affordability of the layer battery cages allows customers to invest in quality equipment without exceeding their budget.

Customer Feedback

Feedback from customers who have implemented Livi Machinery’s layer battery cages in Zimbabwe provides insights into the success and impact of the equipment. Positive feedback highlights improved efficiency, enhanced flock health, and increased egg production.

Conclusion

Embarking on a Project Of 60000 Layers With Chicken Cage Price In Zimbabwe signifies a commitment to modern and efficient poultry farming. The partnership with Livi Machinery not only ensures the availability of high-quality equipment but also provides Zimbabwean customers with valuable support and cost-effective solutions. As the poultry industry in Zimbabwe continues to evolve, the integration of modern equipment becomes a key factor in ensuring sustained success and competitiveness for poultry farmers in the region.

You can leave a message on the message form. We will send you a reply and quotation form within 24 hours.