Chicken scraper cleaning equipment is a vital component in A type layer cage systems, primarily designed to maintain hygiene and cleanliness in poultry farms. Installed below the A-type layer cages, this equipment is used to efficiently remove chicken manure, keeping the environment sanitary and reducing the risk of disease spread.

In this article, we will provide an in-depth guide on the structure, functionality, and advantages of chicken scraper cleaning equipment, followed by a step-by-step installation tutorial. Additionally, an installation video link will be included to help you visually understand the process.

Structure of Chicken Scraper Cleaning Equipment

The chicken scraper cleaning equipment consists of several key components designed to streamline the manure removal process:

- Scraper Blade: The scraper blade is the main component responsible for collecting manure. It is designed to be durable and corrosion-resistant, ensuring long-term use.

- Drive Motor: The drive motor powers the scraper, moving the blade across the manure collection surface beneath the cages.

- Conveyor Belt (or Rope): A rope or belt mechanism is used to move the scraper blade. This system ensures that the blade travels smoothly back and forth to collect and transport manure.

- Guide Rails: These rails help guide the scraper blade along the manure collection area to avoid deviation or obstruction during operation.

- Manure Collection Tray: After the manure is scraped, it is collected in a tray or directed outside the cage system for easy disposal.

Chicken Scraper Cleaning Equipment Installation Tutorial

Functionality of Chicken Scraper Cleaning Equipment in A Type Layer Cage Systems

A type layer cage systems are designed for high-density poultry farming. The chicken scraper cleaning equipment is installed beneath the sloped floors of these cages. The equipment operates by moving the scraper blade across the manure collection area at regular intervals, gathering and pushing the manure towards a central collection point or outside the poultry house.

This manure removal process is automatic, requiring minimal human intervention once installed, and is vital for maintaining a clean, odor-free, and healthy environment for the birds.

Advantages of Using Chicken Scraper Cleaning Equipment

- Improved Hygiene: Regular removal of manure reduces ammonia buildup and limits the risk of infections spreading among chickens.

- Labor Savings: Automating manure removal significantly reduces labor costs and manual effort. With automated control, the scraper can work without constant supervision.

- Environmental Benefits: Proper waste management keeps the surrounding environment clean and lowers the risk of contamination in nearby water sources.

- Longevity: The use of durable materials ensures that the scraper system operates efficiently over a long period, with minimal need for repairs or maintenance.

- Healthier Chickens: A cleaner environment means healthier birds, leading to better egg production rates and overall poultry farm productivity.

Chicken Scraper Cleaning Equipment With A Type Layer Cage Systems

Chicken Scraper Cleaning Equipment Installation Tutorial

Step 1: Prepare the Necessary Tools

Before starting the installation, make sure you have the following tools and materials ready:

- Wrenches and screwdrivers

- Bolts, nuts, and washers

- Measuring tape

- Leveler

- Electrical connections for the motor

- Guide rails, scraper blade, and conveyor chain/belt

- Protective gloves and safety gear

Step 2: Position the Equipment Underneath the Cages

The first step in installing chicken scraper cleaning equipment is to position the equipment below the A-type layer cages. The scraper blade should align perfectly with the manure collection zone under the cages. Use a leveler to ensure the blade will move evenly along the surface.

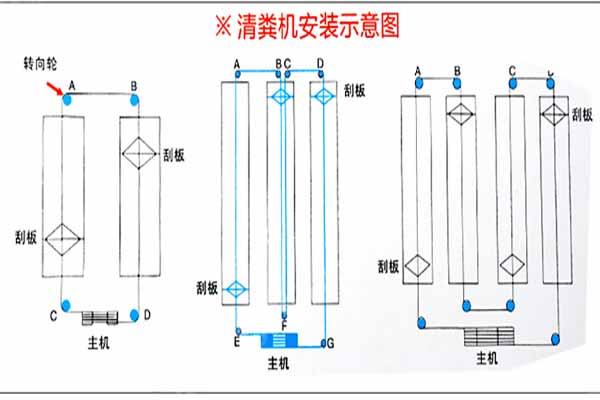

Step 3: Install the Guide Rails

Once the equipment is positioned correctly, install the guide rails on both sides of the collection area. These guide rails will help direct the scraper blade during operation and prevent it from veering off track. Make sure the rails are securely fastened to the cage system framework.

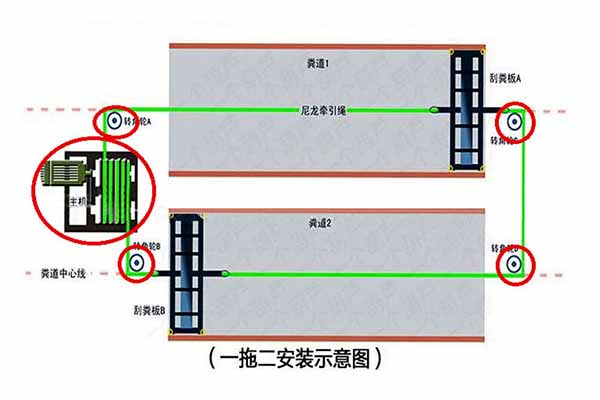

Step 4: Connect the Drive Motor and Conveyor System

Now, connect the drive motor to the conveyor belt or chain system. Ensure that all electrical connections are secure and that the motor is receiving the correct power supply. The conveyor should be fastened tightly to the motor and scraper blade to avoid any slipping during operation.

Step 5: Test the Scraper Blade Movement

Before running the equipment continuously, test the movement of the scraper blade. Switch on the drive motor and observe if the blade moves smoothly across the manure collection tray. If there are any obstructions or issues, make adjustments to the guide rails or conveyor system.

Step 6: Set Automatic Control

Once you confirm that the equipment is functioning correctly, set up the automatic control system. This system will allow the scraper to operate at specific intervals, removing manure without constant manual activation. Adjust the settings according to the needs of your poultry house.

Step 7: Final Adjustments and Maintenance

After installation, perform a final check on all bolts, rails, and electrical connections. Ensure everything is secure and properly adjusted. Regular maintenance is important to ensure the longevity of the equipment, so inspect it periodically for any wear and tear.

Installation Video

For a more detailed visual explanation, please refer to the installation video linked here:

This video will walk you through the steps outlined in the tutorial and provide additional tips for successful installation.

Conclusion

Chicken scraper cleaning equipment is an essential component for maintaining cleanliness and efficiency in A type layer cage systems. Its automated functionality not only improves hygiene but also reduces labor and operational costs. By following the installation guide above and referring to the video tutorial, you can ensure that your poultry farm is equipped with an effective manure removal system, contributing to the health and productivity of your flock.

For more information or questions about the installation process, feel free to contact us.

WhatsApp: +86 17344898347

Email: [email protected]