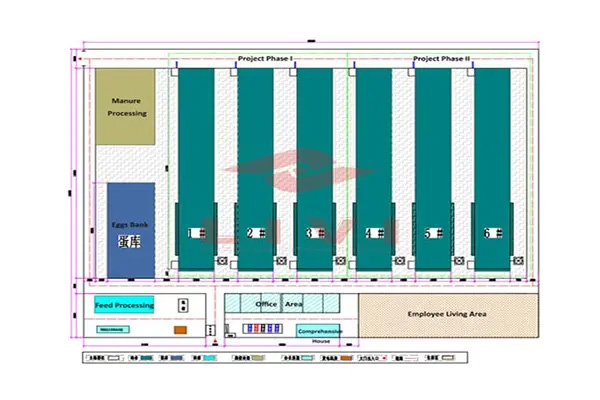

This poultry farm design aims to house 120,000 chickens, divided equally between layers and broilers in a 100*120M chicken farm. The farm utilizes modern automated systems for efficient management, including feeding, waste removal, egg collection, and environmental control.

Poultry Farm Specifications

Total Farm Size: 100m x 120m

Number of Chicken Houses: 6

Dimensions of Each Chicken House: 65m x 10m x 4m

Distribution: 3 houses for layers, 3 houses for broilers

Layers Section

Total Layers: 60,000

Chicken Houses for Layers: 3

Layers per House: 20,000

Housing and Equipment

Layer Cage System: H-type automated layer cages

Cage Details: 4 tiers, 4 doors per tier

Capacity per Cage: 160 layers

Chicken Cages per House: 126 sets

Layout: 3 rows with 42 cages per row

Total Cages Needed: 378 sets (126 sets per house)

Maximum Capacity: 60,480 layers

Automation Systems

Feeding System: Automated feeders ensure consistent and efficient feeding.

Waste Management: Automated manure removal systems transport waste directly to the processing area.

Egg Collection: Automated egg collection systems reduce labor and improve efficiency.

Environmental Control: Automated systems maintain optimal living conditions.

Broilers Section

Total Broilers: 60,000

Chicken Houses for Broilers: 3

Broilers per House: 20,000

Housing and Equipment

Broiler Cage System: H-type broiler cages

Cage Details: 4 tiers, 1 door per tier

Capacity per Cage: 136 broilers

Broiler Cages per House: 162 sets

Layout: 3 rows with 54 cages per row

Total Cages Needed: 486 sets (162 sets per house)

Maximum Capacity: 66,096 broilers

Automation Systems

Feeding System: Automated feeders tailored for broilers.

Waste Management: Automated manure removal systems.

Environmental Control: Systems to regulate temperature, humidity, and ventilation.

Additional Facilities

Manure Processing Area: Equipped with automated manure conveyor systems.

Egg Storage: Specialized storage for collected eggs.

Feed Processing Area: Includes feed mixers for on-site feed production.

Office and Living Quarters: Designed for staff comfort and operational efficiency.

Benefits

Efficiency: Automated systems reduce labor costs and improve productivity.

Hygiene: Automated waste management maintains cleanliness, reducing disease risk.

Productivity: Optimized living conditions promote better growth and egg production.

Scalability: The design allows for easy expansion if needed.

This comprehensive design by Livi Machinery meets the needs of a Ugandan poultry farm owner, ensuring efficient and sustainable management of 120,000 chickens.

If you would like a free chicken design, please leave us a message.